About Mike Kopchick and Rage Fuel Systems

A native of Stratford, Connecticut, Mike Kopchick has been doing machine work since he was nine years old. Mike’s father was a tool and die maker, and Mike spent his summers in the machine shop-full time, every day.

During the late 70s and following an impromptu weekend trip to southern California as a teenager, Mike found his calling after stumbling upon a race car engine building shop, that belonging to Ed Pink. Awestruck by the number of big-name drag racing rigs parked in the lot and getting a sneak peek of rows of engine blocks inside the shop, Mike knew then and there he needed to work for Pink.

“I told Pink I would come in every day to fill out an application until he hired me. He was either going to hire me or run out of paper.”

Four years later, Mike moved on to Keith Black Racing Engines where Wes Cerny was the foreman. Mike stayed with Black for about a year and a half then moved on to Velasco’s Crankshaft Service where he helped build shop tooling. The last stop for Mike on the west coast was at Ed Donovan’s shop. Mike stayed with Donovan for five years before packing up to return back east. The combination of each of these working environments, especially with Donovan, paved the way for Mike’s future businesses.

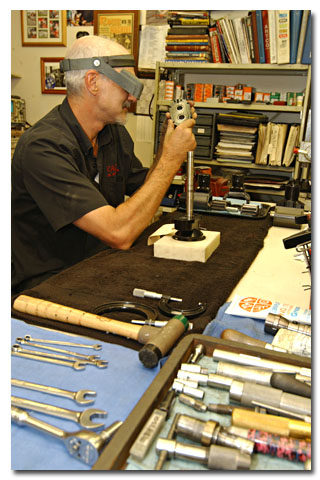

In 1995, Rage Fuel Systems was born. It was Mike’s insistence on precision that led him to build his own fuel pumps. For years he had been modifying and rebuilding other units until he decided that he could control the overall quality of the unit by building it entirely himself.

This is where Mike spends about 90% of his day…in the ‘pump room’.

*The housing is machined out of a single piece of cast iron, whereas his competitors use aluminum. A cast iron pump housing handles heat well, while aluminum housings tend to distort. Though the iron housing is tougher to machine, it solves a problem inherent to aluminum pumps: The pump’s internals would heat up and expand faster than the housing, causing the pump to seize and sometimes break its main shaft.

*Rage pumps use a custom made 1/2-inch diameter shaft, while competitors continue to use a 7/16-inch diameter shaft.

*Rage pumps are designed so that the fuel flows more efficiently to the engine. Close tolerances on the inlet side ensure that no fuel leaks past the pump’s gears, adversely affecting fuel pressure.

*Rage pumps are manufactured and serviced in-house, and have developed an excellent reputation for flow consistency and longevity.

Discover for yourself why these pumps are becoming all the rage. It will more than likely be the last pump you ever buy.